SPL_1011_Z90_HU Roll forming machine

Products > SPL

Show more or BUY when Clicking an Image

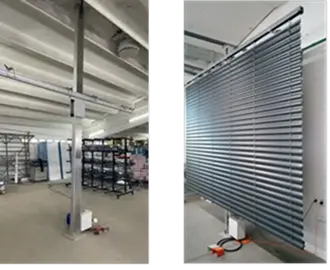

I am thrilled to announce that at SKOVELA d.o.o., we have initiated a revolution in the manufacturing of external venetian blinds. We are introducing our latest slat profiling machine, promising the highest quality, efficiency, and durability thanks to cutting-edge technologies and innovative development.

**Product Highlights and Advantages:**

- **Eco-Friendly Design**: Our machine is constructed from anodized aluminum profiles and plates, benefiting not just the environment but also extending its lifespan.

- **High Quality and Safety**: All electrical cabinets and covers are crafted from stainless steel sourced from EU manufacturers.

- **Intuitive Operation**: A user-friendly program, a result of our in-house development, enables simple operation and remote maintenance of the machine.

- **Flexibility**: The machine is adaptable to various types of slats and sizes.

Furthermore, our company has extensive experience in training local staff worldwide, which enables us to offer you comprehensive customer service.

### Roll Forming Machine for Slats for External Venetian Blinds Z90

This machine is designed for one section type and is suitable for producing external blinds for profile "Z"90. The roll-forming machine is controlled by industrial PLC, with an option for Ethernet connection. The Graphic Display HMI is capable of displaying the shape and the size of the slat cut-in.

**Characteristics:**

- Quick production and accuracy

- Shaping the semi-finished product (aluminum slat) into the desired form

- Cutting the semi-finished product (aluminum slat) to the desired length

- Punching all necessary holes

- Vibration bin for automatic hook supply and infixing in the slats

- Allows for non-standard slat shapes (atypical products)

- Quick and easy change of slat dimensions even during machine operation

- Ethernet (RJ-45) interface

- First year includes technical support services via AnyDesk in the price (assuming the machine is connected to the Internet)

- Manual adjustment of magazine racks

- Easy speed change for rolling

- Possibility of component labeling

- Possibility of connection to an external SQL table (linking machines and information systems)

**Manufacturer**: SKOVELA d.o.o.

**Model**: SPL_1011_Z90_HU

**Year of Construction**: New 2024

**Maximum Width**: 100 cm

**Maximum Height**: 145 cm

**Maximum Overall Length**: 12 m

**SMT Width Left max.**: 114.00 mm

**SMT Thickness min./max.**: 0.40 - 0.44 mm

**Shaft Diameter**: 35 mm

**Vertical Shaft Distance**: 100 mm

**Horizontal Shaft Distance**: 175 mm

**Number of Left Stations**: 11 pcs

## Additional Equipment

### KPH_2M Cutting Table

- Hydraulic driven cutting tool HO7_U5856 for upper profiles

- Equipped with 10 rollers

- Motorized control for profile length, managed via the machine's HDMI interface

- An integrated printer for convenient label generation

- Maximum overall weight: 1150 kg

- Rolling speed: 3 - 12 m/min

- Input pressure: 6-10 bar

- Working pressure: 6 bar

- Air consumption: 5m3/hour

- Power supply voltage: 3+N+PE 400/230V 50Hz TN-S

- Input power: 2.5 kW

- Acoustic pressure: 85 dB

- Customs tariff number: 8455 2200

- Delivery time: 3-6 months

We look forward to your inquiry!

SPL

This rolling machine is designed for one section type and is suitable for production of outside blinds for profile Z90.

Customs tariff number: 8455 2200

Delivery time: 12-16 Week

# Introducing the Revolution in Outdoor Blinds Manufacturing: Our New Louver Profiling Machine by SKOVELA d.o.o.

## Introduction

We are thrilled to present our latest innovation in the manufacturing of outdoor blinds: The Rollforming Machine for Louvers for Outdoor Blinds Z90. Designed and manufactured by SKOVELA d.o.o., this machine sets new standards in quality, efficiency, and longevity thanks to cutting-edge technology and innovative design.

## Product Highlights and Benefits

### Eco-Friendly Design

Our machine is constructed from anodized aluminum profiles and panels, which is not only beneficial to the environment but also extends the machine's lifespan.

### High Quality and Safety

We use stainless steel for all electrical cabinets and covers, sourced from reliable EU manufacturers.

### Intuitive Operation

Our user-friendly program, developed in-house, allows for easy operation and remote maintenance of the machine.

### Flexibility

The machine can effortlessly adapt to various types of louvers and sizes, giving you greater freedom and flexibility in production.

## Technical Specifications

### General Information

- **Manufacturer**: SKOVELA d.o.o.

- **Model**: SPL_1011_Z90_HU

- **Year of Manufacture**: New for 2024

### Dimensions

- **Maximum Width**: 100 cm

- **Maximum Height**: 145 cm

- **Maximum Overall Length**: 12 m

### Technical Data

- **Shaft Diameter**: 35 mm

- **Vertical Shaft Spacing**: 100 mm

- **Horizontal Shaft Spacing**: 175 mm

- **Number of Left-side Stations**: 11 units

- **Material Width and Thickness**: 114.00 mm width and 0.40 - 0.44 mm thickness

### Additional Features

- **Ethernet (RJ-45) Interface**

- **Manual Magazine Rack Adjustment**

- **Easy Roll Speed Modification**

- **First-year technical support via AnyDesk included in the price**

## Optional Equipment: KPH_2M Cutting Table

- **Hydraulically Driven Cutting Tool**

- **Motorized Control for Profile Length**

- **Integrated Printer for Label Creation**

- **Maximum Total Weight**: 1150 kg

- **Roll Speed**: 3 - 12 m/min

## Customer Service

Our company has expertise in training local staff worldwide. Therefore, we can offer you comprehensive customer service that leaves no stone unturned.

## Delivery Time

- **3-6 Months**

We look forward to your inquiry and are happy to answer any further questions you may have!

Customs tariff number: 8455 2200

Delivery time: 12-16 Week

# Introducing the Revolution in Outdoor Blinds Manufacturing: Our New Louver Profiling Machine by SKOVELA d.o.o.

## Introduction

We are thrilled to present our latest innovation in the manufacturing of outdoor blinds: The Rollforming Machine for Louvers for Outdoor Blinds Z90. Designed and manufactured by SKOVELA d.o.o., this machine sets new standards in quality, efficiency, and longevity thanks to cutting-edge technology and innovative design.

## Product Highlights and Benefits

### Eco-Friendly Design

Our machine is constructed from anodized aluminum profiles and panels, which is not only beneficial to the environment but also extends the machine's lifespan.

### High Quality and Safety

We use stainless steel for all electrical cabinets and covers, sourced from reliable EU manufacturers.

### Intuitive Operation

Our user-friendly program, developed in-house, allows for easy operation and remote maintenance of the machine.

### Flexibility

The machine can effortlessly adapt to various types of louvers and sizes, giving you greater freedom and flexibility in production.

## Technical Specifications

### General Information

- **Manufacturer**: SKOVELA d.o.o.

- **Model**: SPL_1011_Z90_HU

- **Year of Manufacture**: New for 2024

### Dimensions

- **Maximum Width**: 100 cm

- **Maximum Height**: 145 cm

- **Maximum Overall Length**: 12 m

### Technical Data

- **Shaft Diameter**: 35 mm

- **Vertical Shaft Spacing**: 100 mm

- **Horizontal Shaft Spacing**: 175 mm

- **Number of Left-side Stations**: 11 units

- **Material Width and Thickness**: 114.00 mm width and 0.40 - 0.44 mm thickness

### Additional Features

- **Ethernet (RJ-45) Interface**

- **Manual Magazine Rack Adjustment**

- **Easy Roll Speed Modification**

- **First-year technical support via AnyDesk included in the price**

## Optional Equipment: KPH_2M Cutting Table

- **Hydraulically Driven Cutting Tool**

- **Motorized Control for Profile Length**

- **Integrated Printer for Label Creation**

- **Maximum Total Weight**: 1150 kg

- **Roll Speed**: 3 - 12 m/min

## Customer Service

Our company has expertise in training local staff worldwide. Therefore, we can offer you comprehensive customer service that leaves no stone unturned.

## Delivery Time

- **3-6 Months**

We look forward to your inquiry and are happy to answer any further questions you may have!

Immediate availability

148000.00 €(DDV ni obračunan v ceni excl.)

Add

Exclusive Offer for Your Investment in Raffstoren Production

Dear [Your Client's Name],

We hope this message finds you well. We are delighted to present our newest, state-of-the-art machines designed explicitly to optimize your investment in the production of Z90 and C80 slats for Raffstoren.

### Detailed Machine Information: SPL_1011_C80

#### Unwinding Section - OT150

- This section is designed for the continuous unwinding of the aluminum strip.

#### Profiling Section with Gear Motor

- Power: 1.5 kW

- This section is responsible for the precise shaping of the slats.

#### Roll-Forming Section for C80

- Specifically developed to meet the demands of C80 slats.

#### Cutting and Punching Hydraulic Tools for C80

- For precise cutting and punching of the slats.

#### Alignment-Smoothing Device for C80 Slats

- This device ensures the perfect alignment and smoothing of the slats.

#### Manual Adjustment: 6-Unit Storage Section with Pneumatic Lift - OND_275_00_L0R6

- Allows for the manual adjustment of the storage section.

- Quantity: 1 pcs

- Price: €75,000.00

### SPL_1210_U58 Roll Forming Machine for Head Rail

- Quantity: 1 pcs

- Price: €75,000.00

- **Special Features**: This machine can either operate as a standalone unit or be online-connected to data from SPL_1011_C80 and SPL_1011_Z90 machines. It customizes upper profiles and simultaneously produces a corresponding label during the cutting process.

### Additional Features: Inspection Panels for Assembling Slats into Raffstoren

- **IP7_40_45_AW**

- Quantity: 2 pcs

- Regular Price: €3,050.00 each

- Discounted Price: €1,525.00 each

- **Special Offer**: 50% discount for a complete and prompt order.

### Direct Savings

Our prices are grounded in manufacturing costs as we are the producers, with no intermediaries involved.

We are confident that this offer will fully meet the requirements of your investors. We have already successfully established similar production lines in Bosnia, Hungary, and Poland.

Should you find this offer to meet your needs, please do not hesitate to contact us for further discussions. We are at your disposal for any clarifications or additional information.

Best Regards,

Exklusives Angebot für Ihre Investition in die Produktion von Raffstoren

Sehr geehrte Damen und Herren,

wir hoffen, Sie sind wohlauf. Es ist uns eine große Freude, Ihnen unsere neuesten, fortschrittlichen Maschinen präsentieren zu dürfen. Diese sind speziell dafür konzipiert, Ihre Investition in die Produktion von Z90- und C80-Lamellen für Raffstoren optimal auszuschöpfen.

### Detaillierte Maschineninformationen: SPL_1011_C80

#### Abwickelabschnitt - OT150

- Dieser Abschnitt ist zum kontinuierlichen Abwickeln des Aluminiumbands vorgesehen.

#### Profilierungsabschnitt mit Getriebemotor

- Leistung: 1,5 kW

- Dieser Abschnitt ist für das präzise Formen der Lamellen verantwortlich.

#### Profilierungsrollenabschnitt für C80

- Speziell entwickelt für die Anforderungen von C80-Lamellen.

#### Schneid- und Stanzhydraulikwerkzeuge für C80

- Zum präzisen Schneiden und Stanzen der Lamellen.

#### Ausrichtungs-Glättungseinrichtung für C80-Lamellen

- Diese Einrichtung sorgt für die perfekte Ausrichtung und Glättung der Lamellen.

#### Manuelle Verstellung: 6 Stück Lagereinheit mit pneumatischem Hub - OND_275_00_L0R6

- Ermöglicht die manuelle Anpassung des Lagerabschnitts.

- Menge: 1 Stk.

- Preis: 75.000,00 €

### SPL_1210_U58 Rollformmaschine für Oberschiene

- Menge: 1 Stk.

- Preis: 75.000,00 €

- **Besondere Merkmale**: Die Maschine kann entweder als eigenständige Einheit betrieben oder online mit den Maschinen SPL_1011_C80 und SPL_1011_Z90 vernetzt werden. Sie erstellt kundenspezifische obere Profile und generiert beim Schneidprozess gleichzeitig eine passende Etikettierung.

### Zusatzfunktionen: Inspektionspaneele für die Montage von Lamellen in Raffstoren

- **IP7_40_45_AW**

- Menge: 2 Stk.

- Regulärer Preis: 3.050,00 € pro Stück

- Rabattierter Preis: 1.525,00 € pro Stück

- **Sonderangebot**: 50% Rabatt bei vollständiger und umgehender Bestellung

### Direkte Ersparnisse

Unsere Preise basieren auf den Herstellungskosten, da wir die direkten Produzenten sind und keine Zwischenhändler beteiligt sind.

Wir sind überzeugt, dass dieses Angebot den Anforderungen Ihrer Investoren vollkommen gerecht wird. Ähnliche Produktionslinien haben wir bereits erfolgreich in Bosnien, Ungarn und Polen implementiert.

Für weitergehende Fragen oder detailliertere Informationen stehen wir Ihnen jederzeit zur Verfügung. Zögern Sie bitte nicht, uns für weiterführende Gespräche zu kontaktieren.

Mit freundlichen Grüßen,

SPL

This rolling machine is designed for one section type and is suitable for production of outside blinds for profile C80 and cutting Head rail 58x56mm.

Customs tariff number: 8455 2200

Delivery time: 12-16 Week

# Machine for Manufacturing Slats for External Venetian Blinds

## Overview:

Our state-of-the-art machine is specifically designed for the production of slats for external venetian blinds of the C80 type. The machine comprises various sections that ensure optimal performance and precision. Below is a detailed description of these different sections and their specifications.

## Left Side of the Machine:

### Uncoiler Section - OT150

- For continuous uncoiling of the aluminum strip.

### Profiling Section with Gearmotor

- Power: 1.5 kW

- Specially designed for accurate shaping of the slats.

### Profiling Roller Section for C80

- Exclusively developed for C80 slats.

### Cut and Punch Hydraulic Tools for C80

- For precise cutting and punching of the slats.

### Align Straightening Device for C80 Slats

- Ensures perfect alignment and smoothing of the slats.

### Manual Adjusting: 6-Piece Storage Unit with Pneumatic Lifting - OND_275_00_L0R6

- Allows for manual adjustment of the storage section.

#### Additional Specifications

- Speed: 6-9 m/min with holes

- Punch for text band with up to 8 holes

- Material used for C80 slats: 94 mm wide aluminum strip.

## Additional Equipment

### KPH_2M Cutting Table

- Hydraulic driven cutting tool HO7_U5856 for upper profiles.

- Equipped with 10 rollers.

- Motorized control for profile length, managed via the machine's HDMI interface.

- An integrated printer for label generation for your convenience.

## Control and Interfaces

- PLC Cybro and HMI Weitek 7" control.

- Ethernet (RJ-45) and WiFi interface.

## Technical Support

- Remote control technical support is included in the price during the warranty period (assuming the device is connected to the Internet).

## Drive and Power

- Reduction gear control with frequency regulator.

- Voltage: 3x240V/400V, 50Hz, 3x6A.

- Pneumatics: Air pressure 6 bar, 60 l/min.

## Dimensions and Additional Data

- (L*W*H) 900x90x160 cm

- Customs Tariff Number: 8455 2200

- Country of Origin: EU

- Date of Production: 2024

- Machine Number: 24__

Customs tariff number: 8455 2200

Delivery time: 12-16 Week

# Machine for Manufacturing Slats for External Venetian Blinds

## Overview:

Our state-of-the-art machine is specifically designed for the production of slats for external venetian blinds of the C80 type. The machine comprises various sections that ensure optimal performance and precision. Below is a detailed description of these different sections and their specifications.

## Left Side of the Machine:

### Uncoiler Section - OT150

- For continuous uncoiling of the aluminum strip.

### Profiling Section with Gearmotor

- Power: 1.5 kW

- Specially designed for accurate shaping of the slats.

### Profiling Roller Section for C80

- Exclusively developed for C80 slats.

### Cut and Punch Hydraulic Tools for C80

- For precise cutting and punching of the slats.

### Align Straightening Device for C80 Slats

- Ensures perfect alignment and smoothing of the slats.

### Manual Adjusting: 6-Piece Storage Unit with Pneumatic Lifting - OND_275_00_L0R6

- Allows for manual adjustment of the storage section.

#### Additional Specifications

- Speed: 6-9 m/min with holes

- Punch for text band with up to 8 holes

- Material used for C80 slats: 94 mm wide aluminum strip.

## Additional Equipment

### KPH_2M Cutting Table

- Hydraulic driven cutting tool HO7_U5856 for upper profiles.

- Equipped with 10 rollers.

- Motorized control for profile length, managed via the machine's HDMI interface.

- An integrated printer for label generation for your convenience.

## Control and Interfaces

- PLC Cybro and HMI Weitek 7" control.

- Ethernet (RJ-45) and WiFi interface.

## Technical Support

- Remote control technical support is included in the price during the warranty period (assuming the device is connected to the Internet).

## Drive and Power

- Reduction gear control with frequency regulator.

- Voltage: 3x240V/400V, 50Hz, 3x6A.

- Pneumatics: Air pressure 6 bar, 60 l/min.

## Dimensions and Additional Data

- (L*W*H) 900x90x160 cm

- Customs Tariff Number: 8455 2200

- Country of Origin: EU

- Date of Production: 2024

- Machine Number: 24__

Immediate availability

83000.00 €

Add

SPL

This rolling machine is designed for one section type and is suitable for production of outside blinds for head rail profile U58.

This machine is equipped without tools for holes

Customs tariff number: 8455 2200

Delivery time: 12-16 Week

This machine is equipped without tools for holes

Customs tariff number: 8455 2200

Delivery time: 12-16 Week

Immediate availability

90000.00 €

Add

IP7 Assembly Elevator

Elevator assembly for the assembly of aluminium EVB External venetian blinds determined.

TYPE IP7

CURRENT 1 PHASE, 220V, 50HZ

MAX. HIGTH 450 cm

MAX. LENGTH 650 cm

DIM 450/50/450cm

DIM OF PACKING 460/60/60cm NW 92kg

Customs Tariff: 8428 10 20

Delivery time: 1-3 weeks

TYPE IP7

CURRENT 1 PHASE, 220V, 50HZ

MAX. HIGTH 450 cm

MAX. LENGTH 650 cm

DIM 450/50/450cm

DIM OF PACKING 460/60/60cm NW 92kg

Customs Tariff: 8428 10 20

Delivery time: 1-3 weeks

Immediate availability

3000.00 €

Add

Sale agreement Nr.:

Appendix No. 2 to sale agreement Nr.: TECHNICAL ACCEPTANCE PROTOCOL

Appendix No. 3 to sale agreement Nr.: DELIVERY PROTOCOL

Appendix No. 4 to sale agreement Nr.: ACCEPTANCE PROTOCOL

Appendix No. 3 to sale agreement Nr.: DELIVERY PROTOCOL

Appendix No. 4 to sale agreement Nr.: ACCEPTANCE PROTOCOL

Show more or BUY when Clicking an Image

Service cordination

EVB Parts

Stroji za proizvodnjo zunanjih žaluzij

Persianas venecianas exteriores de oscurecimiento aluminio

Rollformer / Rollformmaschine Profilen für Raffstoren.

Persianas venecianas y cortinas exteriores

Raffstoremaschine für Raffstoren und Außenjalousien.

Le profilage à froid est une déformation progressive en continu d?une bande d?acier par un nombre de galets définis en fonction de la section souhaitée.

Walzprofilieren ist ein kontinuierliches Biegeverfahren, bei dem Bandmaterial aus Blech von einer Anzahl Walzenpaaren schrittweise umgeformt wird.

Roll forming is a continuous bending process in which strip material from sheet metal is gradually formed by a number of roller pairs.

Formimi i rrotullimit është një proces i vazhdueshëm i përkuljes në të cilin materiali i shiritit nga fleta metalike formohet gradualisht nga një numër i çifteve rul.

Формирането на ролките е процес на непрекъснато огъване, при който материалът за ленти от листов метал постепенно се формира от няколко ролкови двойки.

Raffstoren und Jalousien Gebördelte Raffstoren Flache Lamellen Außenjalousien

outdoor blinds and Venetian blinds

I frangisole e le veneziane

A raffstore-ok és zsaluziák

Рафшторы и жалюзи

Vanjske raffstore žaluzine i žaluzine

Рафштори та жалюзі

Jaluzele exterioare din aluminiu

żaluzje fasadowe i żaluzje

Venkovní žaluzie a žaluzie

Storurile și jaluzelele

Raffstory a žalúzie

Zunanje Beneške žaluzije in zunanje žaluzije

Dış Cephe Jaluziler

External Venetian Blind

Fasadepersienner og persienner

Raffstores en jaloezieën

Les brise-soleil et les jalousies

Fasadpersionner och jalusier

Lamellen Typ

Z90

C80

S93